Tips for Fibre Cable Installation

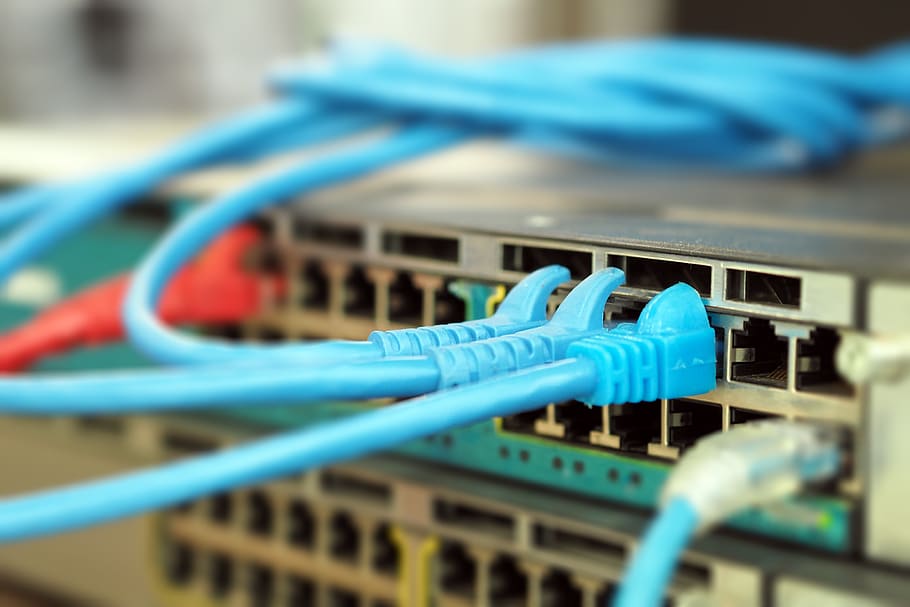

A good installation of fibre cables ensures their precise and continuous working over the years. The right installation can minimize the chances of repairs and maintenance in the near future. Therefore, technicians should take special care while the installation of fibre cables in any setting.

However, the installation is not easy, and professionals need to take care of many things. From, handling the cable to twisting, pulling, rolling and making connections precisely, there are many things to consider. This post shares all the tips required for a precise installation of fibre cables.

Plan the installation

The best a technician can do for a precise installation is to plan everything before execution. By creating a detailed plan for the installation, you can eliminate maximum problems. While creating a plan, write every detail about the equipment required, specification of fibre cable, equipment location, testing requirements, potential problems, safety issues, and the method of installation.

Pulling load rating

Technicians should never exceed the maximum pull load rating. The glass fibre in the optical fibre cables is delicate, and the most common type of damage is caused due to excessive tension. Technicians should always keep the tension lower than the recommended limit while installing a cable.

Use lubricants on the long runs, but they should be compatible with the cable jacket. On more long runs, pull the fibre out to the ends from the middle. It is best to use an automatic puller that comes with the tension control feature. Check the maximum load rating before working on any cable.

Quality of fibre cable

It is essential to confirm the quality of the fibre cable before buying it for any project. Also, the technicians should test the quality of cable before installation. If the product shows no sense of damage, you can test the cable using a continuity tracer tool. If all the fibres in a cable transmit light, the quality is considered as good. If there is a hint of damage to the fibre cable, it should be tested for its quality to decide whether you should use it or not. If you have already installed the cable, you can also perform a post-installation test. An issue may also arise due to excessive pulling or some other reason.

Bend Radius

Another important factor in the installation of fibre cables is to maintain the minimum bend radius. The fibres are strong as steel when they are straight, but they become weak when bent. Bending of fibre cable more than the minimum bend radius will lead to broken fibres. If the cable elements are not damaged during bending, the attenuation should return back as soon as the bend is relaxed.

Monitor the supply reel

It is essential to monitor the supply reel during the installation of fibre cable to avoid the violation of the minimum bend radius.

Roll the cable of the spool

Never spin the cable of the spool end. Instead, roll it off the spool every time you use a new cable. Spinning the cable can put a twist in the fibre. The twist puts stress on the fibre that may cause it to break.

Never exceed the maximum vertical rise

Every optical fibre cable comes with a maximum vertical rise value. It is a function of the cable’s tensile strength and weight. The value represents the maximum vertical distance upto which the cable can be installed without any support points. Technicians should never exceed the maximum vertical distance while installing an optical fibre cable.

Use the right length of cable

Always check the length of the cable before installation. The fibre cable should be long enough for the complete run. Splicing fibre cable can make things complicated and increase the cost. Also, fibre splicing requires special skills and protection. So technicians should always try to make it in one pull.

Communicate along the installation path

Technicians should monitor and communicate around the part of the installation. Optical fibre cables can jump from pulleys if not monitored. The minimum crew should have at least one person to monitor the pulling equipment, and one to monitor the supply reel and another one to coordinate everything involved in the process of installation.

Test the installation

Technicians should always test the working of cables after installing them in any network. You can test the installation using the network cable testers to check its precision. Testing enables technicians to know whether everything works well or needs improvement.

Covertel offers networking, monitoring, telecommunication and network testing services to organisations in Australia. They offer services to businesses and government and defence organisations. They also offer products like network cable testers, wifi equipment, network analyzers and monitoring equipment. Businesses in Australia can contact them for any of these services. Visit their website to know about their services in detail.

Final Words

These are some tips for installation of fibre cables in any network. Creating an installation plan and monitoring everything can help technicians to install the fibre cables with high precision. The key to installing fibre cables is to work in a team and assign the work to individuals as per their skills and experience.